Despite its many different uses, for centuries the most faithful ambassador of cork to the world has been the natural cork stopper, that seal of exceptional quality that is still today preferred and demanded by the great wine producers. However, throughout History there have been numerous references to this product and its varied applications. In 3000 BC, cork was already being used in fishing tackle in China, Egypt, Babylon and Persia. In Italy remains dating from the 4th century BC have been found that include artifacts such as floats, stoppers for casks, women’s footwear and roofing materials. Also dating from that period is one of the first references to the cork oak, by the Greek philosopher Theophrastus who, in his botanical treatises, referred in wonder to “the ability that this tree has to renew its bark after it has been removed”.

Wine and cork are two products that have long been companions. Proof of this is an amphora from the 1st century BC found in Ephesus: it was not only was sealed with a cork stopper but also still contained wine. Later, in the 1st century CE, the Roman naturalist Pliny the Elder made extensive reference to cork oaks in his celebrated Natural History. He explained that in Greece the trees were adored as symbols of liberty and honour, for which reason only priests were allowed to cut them down. In the same work, we can read that cork oaks were consecrated to the god of Olympus, Jupiter, and their leaves and branches were used to crown victorious athletes. In Pompeii, the Roman city destroyed by the brutal eruption of Mount Vesuvius, wine amphorae sealed with cork have also been found.

Portugal can be proud to have been a pioneer in environmental legislation, the first agrarian laws protecting cork forests having been enacted in the early 13th century, in 1209. Later, during the Age of Discoveries, the builders of the Portuguese ships and caravels that set sail in search of new worlds used cork oak wood for the parts that were most exposed to inclement weather. They claimed that the “sôvaro”, as it was called then, was the best wood for masts and yards: besides being exceptionally strong, it never rotted.

In the 18th century, while in England the physician Robert Hooke obtained the first microscopic images of cork using a microscope that he himself had designed, in France, the monk Dom Pierre Pérignon, treasurer of the Hautvillers Abbey, began to use cork to seal bottles of his famous Dom Pérignon champagne. A choice that continued over the years and is still maintained.

However the systematic cultivation of the great cork forests that characterize the Iberian Peninsula and can still be found in Catalonia and Portugal, dates only from 18th century, when the production of cork stoppers became the main objective. This was also when the first studies were made of its chemical composition by the Italian chemist Brugnatelli, and the first compendium on cork oak culture, “Azinheiras, Sovereiras e Carvalhos da Província de Além-Tejo”, was published in Portugal in 1790 by Joaquim Sequeira.

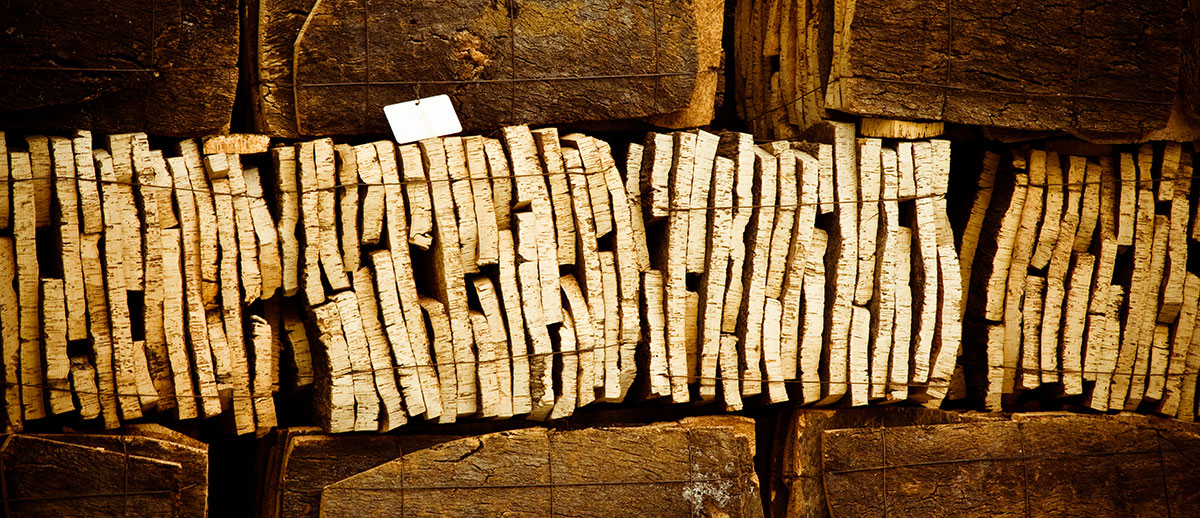

In the 19th century, France, Italy and Tunisia invested in the systematic planting of cork forests and countries as different as Russia or the United States also started planting cork oaks. It was a century marked by significant developments in the cork stopper industry: in the United Kingdom the first cork stopper manufacturing machine was patented, and auxiliary equipment was invented, such as cork stopper counting and calibrating machines. For the first time, new industrial applications for cork were used, such as simple or white agglomerate for flooring discovered by the Americans. In the last years of the century, in Reims, France, the first two piece glued natural cork stoppers began to be manufactured.

In the next century, the cork industry in the different cork-producing countries began to invest more in innovation and development, launching various new products onto the market. In 1903, cork stoppers with natural cork discs and a body of agglomerate first appeared. Some years later, patents were registered for the use of cork in transmission belts and tires and during the Second World War, this material was used in many pieces of military equipment. In the 1950s, an American company produced the first agglomerated cork tiles with a vinyl film covering. In recent decades, various initiatives have emerged aimed at research and the definition of international standards for the cork industry, including the Confédération Européenne du Liège (C.E. Liège), founded in 1987. Formed by cork federations from various countries, this organization presented in 1996 the International Code of Cork Stopper Manufacturing Practice, a key document for quality control in the production of cork stoppers. This document describes and regulates the corresponding manufacturing processes and is still being permanently revised and updated in accordance with increasingly demanding levels of quality. Only two years earlier, another initiative, the Quercus Programme, had been set up with the support of the European Commission and C.E. Liège, to diagnose and eliminate the causes and components of the detested “taint”, clearly a problem that is being solved.

Finally, all the signs are that in the 21st century, cork will again enjoy the respect and admiration that the Greeks and Romans afforded it as a noble and adaptable material. Not only has the reputation of natural cork stoppers as the quintessential seal remained untouched, but in this century in which environmental concerns have became a constant, the use of a ecological, recyclable and biodegradable material such as cork has increased, particularly in innovative areas such as Design for Sustainability and Eco-Design. Increasingly, new generations of artists seek to create everyday objects – articles for the table, kitchen, leisure, furniture – from the “fruits of the earth”, materials that are one hundred per cent natural and contribute to environmental sustainability. In Portugal, for example, interest in the potential of cork has grown exponentially. Recently, the market was presented with an absolute innovation: a car seat with a base made from cork which halved its volume and made it three times lighter than traditional seats. The extraordinary thing about this invention is that each of these new seats can reduce the weight of a normal car by 45 kilos, thus helping to resolve two of the major problems of the automotive industry, weight and volume. Made from 60% ground cork, this cushion, besides offering the same comfort with half the volume, has the added benefit of being recyclable. The seat is a national project conceived entirely by Portuguese know-how – design, technical and scientific support –, and although it is still at a prototype stage, it has already captivated Magna, the world leader in automotive parts which has made orders worth more than 300 million euros.

* “History of Cork” courtesy of APCOR, www.realcork.org